Rick Feltenberger is an established thought leader in the world of Logistics, Supply-Chain Operations and Technology.

An alumnus of The University of Tennessee, Rick is also a former Green Beret and Vice-President at DirectTV, and now acts as Principal of the Supply Chain Center, which he has operated for the better part of a decade. A LinkedIn "One-Percenter" and social media auteur, Rick was kind enough to discuss some major topics with us in his areas of expertise, namely the future of operations management and effiency.

1. How have you seen the world of logistics and the supply-chain industry change?

It is almost frightening to think that there was a time when people couldn’t get an MBA in Supply Chain Management; but there was a time!

When I started out, the world of logistics was rather drab and uninviting. It was a world of dingy warehouses with guys (not many women in the field back in the day) in tank-top T-shirts drinking beer and driving forklifts. They always had great ideas, but few people would listen to them. There was only one solution to every problem: Throw money and people at the problem until the immediate “fire” was put out.

Fortunately, we moved from manual processes and firefighting into the world of ERP during the 1980s. Systems, data, unknown processes, and mixed results were the norm. Using technology to manage freight and transportation was only a pipe dream at the time, as was having suppliers integrated into the mix. It was better than what we had, but not by much because we had a disconnect between physical processes and ERP systems. The era of functional silos emerged!

In the 1990s, Innovation became important in logistics and the term “Supply Chain Management” (which few people really understood) was vogue. We had to figure out a way to make the investment in ERP payoff. The old Information Systems department became Information Technology and more and more software was touted as the “supply chain solution” and many companies poured millions of dollars into technology, most with little to show for their efforts. Executives started to demand higher performance with fewer resources to make-up the shortfall. Systems improved but we still operated in silos.

At the turn of the century, we all started to get smarter. MBAs in Finance were replaced with MBAs in Supply Chain Management, most of whom had significant industry experience in the supply chain before they received their degree. Integration was coupled with Innovation and we could start to see the development of what I called Real Supply Chains, which extended from the end customer, throughout the entire enterprise, and into a vast base of suppliers. Silos started to fall, we leveraged technology to communicate WITH each other and not just TO each other, and Global became the reality.

Today, we live in a complex world of logistics and supply chain management that truly spans the globe. We still have issues that need to be resolved, but I am looking from the perspective of a long journey to a totally new and promising frontier.

2. What were the keys to building & sustaining a successful logistics enterprise in The Supply Chain Center?

Reflecting on our first decade of success and pondering the future, I believe that there are really three sets of keys to unlock the successful logistics and supply chain enterprise.

The first is building the capacity to identify and address Real Problems and not just treat symptoms. When organizations view their extended enterprise supply chain as a bunch of internal functions, they often see only symptoms and miss the overarching problem. This, of course, leads to unhappy customers, poor operational performance, and missed financial opportunities.

The second is having a process-based approach that delivers results without the need for more “software” in the mix. Many notable research organizations have consistently found that nearly 70% of major technology initiatives fail to deliver the financial results which companies anticipated. It wasn’t “bad” technology; it was simply that many Executives bought-in to the notion that flipping a switch produced a Supply Chain solution…it doesn’t. Sustainability comes from a solid foundation of integrated and well thought-out processes. Technology can help, but only after robust processes are adequately established.

The third key is attracting & retaining people. I don’t need to tell you that recent studies have shown that over 80% of employees are disengaged at some level. I see part of the solution as Organizational Culture. Many companies only pay lip-service to their Mission, Vision, and Values. The M/V/V are what the Organizational Culture is built upon and to be successful, they must reflect what actually occurs within their 4-walls. That is a scary thought for some companies! To attract & retain smart, engaged, and immensely productive people who know the processes, are excited about coming to work, anticipate problems, and present solutions, companies must transform failing cultures.

3. Name the biggest challenges right now within the supply-chain/logistics industries?

With all of the time, treasure, and talent that has been poured into the supply chain/logistics industry we really haven’t paid attention to the customer. The challenge is that many companies see an interesting innovation, such as Amazon’s drones and same-day delivery initiatives, and then they follow a “me too” strategy thinking that they can ride the coattails of innovation and customers will flock to them. It doesn’t work like that.

To meet and exceed customer expectations we must understand the customer. Companies must understand how their ideal customer “buys” Value (my friend Michael Treacy calls them "Value Disciplines" in his book, The Discipline of Market Leaders). Then they must structure their Operational Model to meet that particular Value. For example, if a customer only sees Value in the lowest total cost, it makes no sense for a company to invest their time, treasure, and talent into divergent Value Disciplines which are of no interest to their ideal customer.

It is a little more complex than I have explained, but it isn’t rocket science. We must KNOW & LISTEN to the Customer and respond appropriately.

4. What is your management style and why?

My style is probably weird!

I value People, Processes, and being part of something Special…contributing to something greater than the sum of the parts. I always create & propagate a picture of Success with supporting operational & financial metrics so that everyone knows what Success ‘looks’ like. I tend to be passionate, agile-thinking, goal-oriented, and a voracious problem solver. My tendency is to spend more time making sure that I have identified the correct problem. Often I work alone in this process and only seek collaboration to get additional data. It’s just the way I work.

After identifying the correct problem, I’m quick to bring others into the process for validation and charting potential courses of action. I collaborate with everyone who could possibly be impacted by the problem/solution. I build or expand my team with great talent. I try to obtain 90% buy-in to the problem and solution while having that special 10% of skepticism. I’m demanding, fair, and like to have fun, expecting others to be that way too.

My Myers-Briggs type is INTJ. I’ve spent a lot of time making sure that I have built upon the best aspects of this personality type and mitigated the shortcomings that are typically identified with the traditional INTJ. As an Army Officer, I had the privilege of serving 3 tours in Special Forces (the “Green Berets”) where I learned leadership from some of the most decorated, honored, and successful people in the world. It was easy to transfer those learnings into the commercial world. I really hate to mention these things because actually I’m humbled by the experience. I only provide it to give you some deeper background into my management style.

5. What are the emerging trends that you see in supply-chain management and logistics?

Some of the more promising trends are Omni-Channel, Supply Chain Sustainability, and extending Collaboration deeper and deeper into both ends of the Supply Chain. I could be wrong, but I don’t think drones and same-day delivery are ready for prime time…yet!

6. What advice would you give to a new graduate entering the logistics/supply-chain field?

Learn the basics. Understand the blocking & tackling which always must be accomplished regardless of the industry within the logistics/supply chain field you choose. Work in several industries and take the best practices you find into your new jobs. Don’t be a “this is how we did it in company X” type of person, but be able to apply the principles you learned to new situations.

Take on tough challenges, take calculated risks, and don’t be afraid of rocking the boat when you are absolutely certain of your solutions. Never fail; mistakes are fine, but never fail. Be able to reverse course when you have supporting data and ALWAYS have the data. Never be afraid to admit that you were wrong. Have fun; life is too short to be miserable! Find Rick on Twitter and LinkedIn.

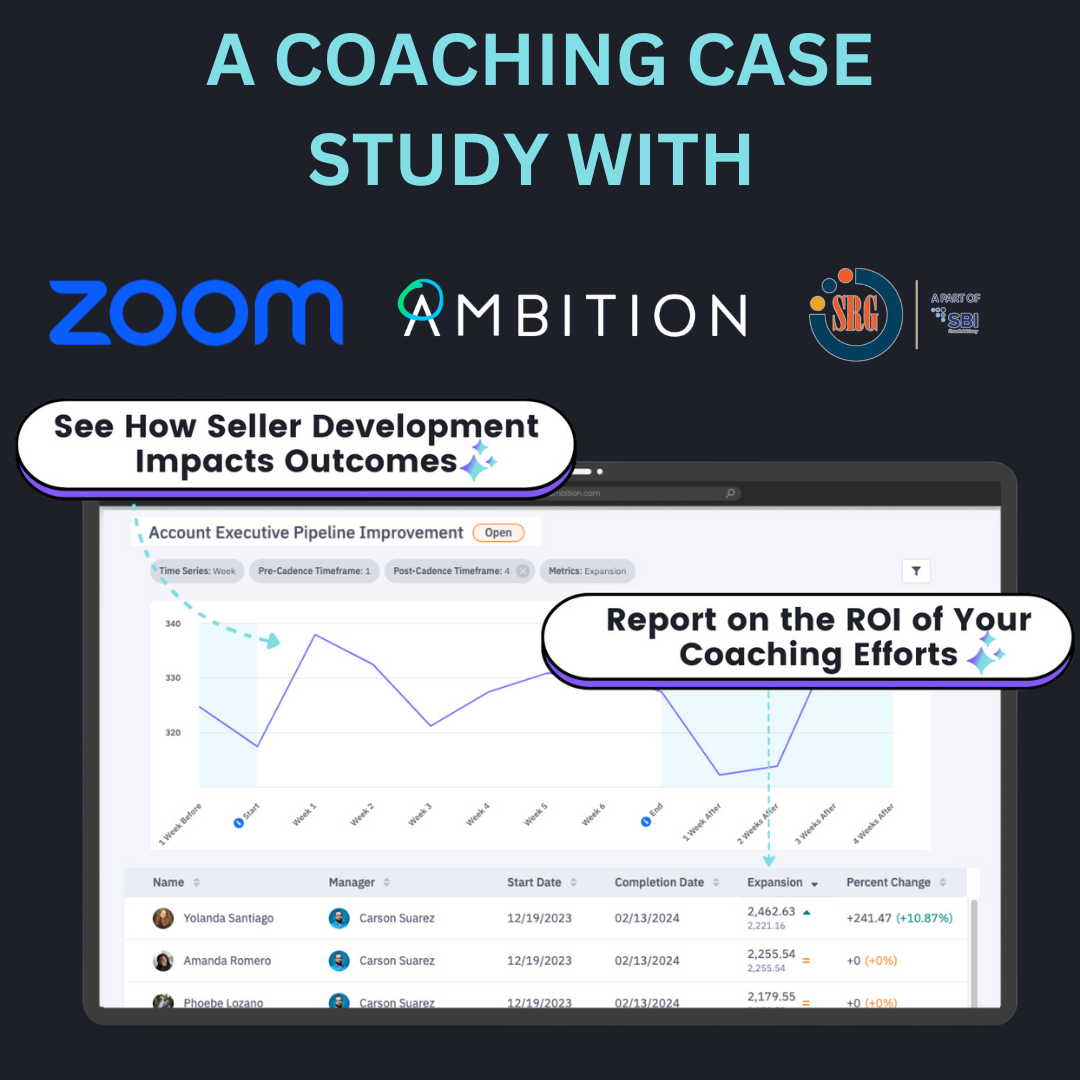

Ambition: Sales Performance Accountability for 3PLs

Ambition is a sales management platform that syncs every sales organization department, data source, and performance metric on one easy system.

Ambition clarifies and publicizes real-time performance analytics for your entire sales organization. Using a drag-and-drop interface, non-technical sales leaders can build custom scorecards, contests, reports, and TVs.

Ambition is endorsed by Harvard Business Review, AA-ISP (the Global Inside Sales Organization), and USA Today as a proven solution for managing millennial sales teams. Hear from our customers below.

Watch Testimonials:

- FiveStars: Adam Wall. Sr. Manager of Sales Operations .

- Filemaker: Brad Freitag. Vice-President of Worldwide Sales.

- Outreach: Mark Kosoglow. Vice-President of Sales.

- Cell Marque: Lauren Hopson. Director of Sales & Marketing.

- Access America Transport: Ted Alling. Chief Executive Officer.

Watch Product Walkthroughs:

- ChowNow. Led by Vice-President of Sales, Drew Woodcock.

- Outreach. Led by Sales Development Manager, Alex Lynn.

- AMX Logistics. Led by Executive Vice-President ,Jared Moore.

Read Case Studies:

- Clayton Homes: HBR finds triple-digit growth in 3 sales efficiency metrics.

- Coyote Logistics: Monthly revenue per broker grew $525 in 6 months.

- Peek: Monthly sales activity volume grew 142% in 6 months.

- Vorsight: Monthly sales conversations grew 300% in 6 months.

Contact us to learn how Ambition can impact your sales organization today.

Back

Back